Pehea e koho ai i ka Surface Finish no kāu PCB Design

Ⅲ Ke alakaʻi koho a me ka hoʻomohala ʻana i nā ʻano

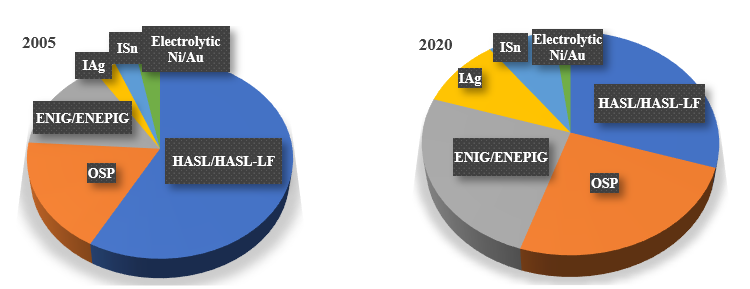

E like me ka hōʻike ʻana o ka pakuhi i luna, ua ʻano like ʻole ka noi ʻana o ka PCB surface i nā makahiki he 20 i hala iho nei e like me ka hoʻomohala ʻana o ka ʻenehana a me ke alo o nā kuhikuhi pili kaiapuni.

1) HASL Lead Free.Ua emi nui ka uila i ke kaumaha a me ka nui me ka ʻole o ka kaumaha ʻana i ka hana a i ʻole ka hilinaʻi i nā makahiki i hala iho nei, ka mea i kaupalena i ka hoʻohana ʻana i ka HASL i ka nui i loaʻa ʻole ka ʻili a ʻaʻole kūpono i ka pitch maikaʻi, BGA, nā mea liʻiliʻi i hoʻokomo ʻia a hoʻopaʻa ʻia ma nā lua.He hana maikaʻi loa ka hoʻopau ʻana o ka ea wela (hilinaʻi, solderability, ka noho ʻana o ka pōʻai wela a me ke ola lōʻihi) ma ka hui PCB me nā pā nui a me ka spacing.ʻO ia kekahi o ka hoʻopau kūpono loa a loaʻa.ʻOiai ua hoʻololi ʻia ka ʻenehana HASL i ka hanauna hou o HASL alakaʻi ʻole i ka hoʻopaʻa ʻana i nā palena RoHS a me nā kuhikuhi WEEE, ua hāʻule ka pae wela wela i ka 20-40% i ka ʻoihana hana PCB mai ka noho aliʻi ʻana (3/4) i kēia wahi ma 1980s.

2) OSP.Ua kaulana ʻo OSP ma muli o ke kumukūʻai haʻahaʻa a me ka hana maʻalahi a me ka loaʻa ʻana o nā pad co-planar.Hoʻokipa mau ʻia no kēia.Hiki ke hoʻohana nui ʻia ke kaʻina hana hoʻopili kūlohelohe ma nā PCB maʻamau a i ʻole nā PCB kiʻekiʻe e like me ka pitch maikaʻi, SMT, nā papa lawelawe.ʻO ka hoʻomaikaʻi hou ʻana i ka pā multilayer o ka uhi organik e hōʻoia i ka kū ʻana o OSP i nā pōʻai he nui.Inā ʻaʻole i loaʻa i ka PCB nā pono hana pili pili honua a i ʻole nā palena o ke ola, ʻo OSP ke kaʻina hana hoʻopau maikaʻi loa.Eia nō naʻe, ʻo kona mau hemahema, ka naʻau i ka mālama ʻana i ka pōʻino, ke ola pōkole, ka nonconductivity a me ka paʻakikī ke nānā ʻana e hoʻolohi i kāna ʻanuʻu i ʻoi aku ka ikaika.Ua manaʻo ʻia aia ma kahi o 25% -30% o nā PCB i kēia manawa ke hoʻohana nei i kahi kaʻina hoʻopili organik.

3) ENIG.ʻO ENIG ka hopena kaulana loa ma waena o nā PCB kiʻekiʻe a me nā PCB i hoʻohana ʻia i loko o ke kaiapuni paʻakikī, no kāna hana maikaʻi loa ma ka papahele planar, solderability a me ka lōʻihi, ke kū'ē i ka tarnish.Loaʻa ka hapa nui o nā mea hana PCB i nā laina gula electroless / immersion gula i kā lākou mau papa hana kaʻapuni a i ʻole nā hale hana.Me ka noʻonoʻo ʻole i ke kumukūʻai a me ke kaʻina hana, e lilo ʻo ENIG i nā koho kūpono o HASL a hiki ke hoʻohana ākea.Ke ulu wikiwiki nei ka nickel / immersion gula ʻeleʻele i ka makahiki 1990 ma muli o ka hoʻoponopono ʻana i ka pilikia palahalaha o ka pae ʻana o ka ea wela a me ka wehe ʻana i nā kahe i uhi ʻia.ʻO ENEPIG ma ke ʻano he mana hou o ENIG, ua hoʻoponopono i ka pilikia pad ʻeleʻele o ka nickel electroless/immersion gula akā ʻoiai ke kumu kūʻai.Ke lohi iki nei ka noi ʻana o ENIG mai ka piʻi ʻana o ke kumu kūʻai liʻiliʻi e like me Immersion Ag, Immersion Tin a me OSP.Ua manaʻo ʻia ma kahi o 15-25% o nā PCB i kēia manawa e hoʻopaʻa i kēia hoʻopau.Inā ʻaʻohe hoʻopaʻa kālā, ʻo ENIG a i ʻole ENEPIG kahi koho maikaʻi loa ma ka hapa nui o nā kūlana, ʻoi aku ka nui o nā PCB me nā koi koi nui o ka ʻinikua kiʻekiʻe, nā ʻenehana paʻakikī paʻakikī, nā ʻano kūʻai he nui, nā lua, ka hoʻopaʻa ʻana i ke kelepona, a me ka ʻenehana kūpono. etc..

4) Kālā Kaiapuni.Ma ke ʻano he pani haʻahaʻa loa o ENIG, ke kala kaiapuni i loaʻa nā waiwai o ka loaʻa ʻana o ka ʻili palahalaha, ka hoʻokō maikaʻi ʻana, ke ola mālama haʻahaʻa.Inā makemake kāu PCB i ka pitch maikaʻi / BGA SMT, hoʻokomo i nā mea liʻiliʻi, a pono e mālama i ka hana pili pono ʻoiai he haʻahaʻa kāu kālā, ʻo ke kālā kaiapuni kahi koho maikaʻi loa iā ʻoe.Hoʻohana nui ʻia ʻo IAg i nā huahana kamaʻilio, nā kaʻa, a me nā peripherals kamepiula, a me nā mea ʻē aʻe.Ke lohi nei ka ulu ʻana o ke kālā kaiapuni (akā e piʻi mau ana i luna) ma muli o nā ʻaoʻao haʻahaʻa o ka noʻonoʻo ʻana i ka ʻeleʻele a me ka loaʻa ʻana o nā hakahaka o nā hui solder.Aia ma kahi o 10% -15% o nā PCB e hoʻohana nei i kēia hoʻopau.

5) Pākuʻi ʻia.Ua hoʻokomo ʻia ka Immersion Tin i loko o ke kaʻina hana hoʻopau ʻili no nā makahiki he 20.ʻO ka automation hana ka mea hoʻokele nui o ka hoʻopau ʻana i ka ʻili o ISn.ʻO ia kekahi koho kumu kūʻai no ka pono o ka ʻili palahalaha, ka hoʻokomo ʻana i nā ʻāpana pitch maikaʻi a me ka press-fit.He kūpono loa ʻo ISn no nā mokulele hope kamaʻilio no nā mea hou i hoʻohui ʻia i ka wā o ke kaʻina hana.ʻO Tin Whisker a me ka puka makani pōkole ka palena nui o kāna noi.ʻAʻole ʻōlelo ʻia nā ʻano hui he nui i ka hoʻonui ʻia ʻana o ka papa intermetallic i ka wā kūʻai.Eia kekahi, ua kaupalena ʻia ka hoʻohana ʻana i ke kaʻina hana immersion ma muli o ka loaʻa ʻana o nā carcinogens.Ua manaʻo ʻia aia ma kahi o 5% -10% o nā PCB e hoʻohana nei i ke kaʻina hana immersion tin.

6) Electrolytic Ni / Au.ʻO Electrolytic Ni / Au ka mea nāna i hoʻokumu i ka ʻenehana lapaʻau ʻili PCB.Ua puka mai me ka pilikia o na papa kaapuni pai.Eia nō naʻe, ʻo ke kumukūʻai kiʻekiʻe loa e kaupalena ʻia kāna noi.I kēia mau lā, hoʻohana nui ʻia ke gula palupalu no ka uwea gula i loko o ka puʻupuʻu chip;Hoʻohana nui ʻia ke gula paʻa no ka pilina uila ma nā wahi kūʻai ʻole e like me nā manamana gula a me nā mea lawe IC.ʻO ka hapa o ka Electroplating Nickel-gold ma kahi o 2-5%.

Ke kuai Blogs

Ka manawa hoʻouna: Nov-15-2022